Dredging is what we do to haul up rocks from the ocean floor and seamounts. It is a basic and rudimentary technique (Figure 1) that has been around since the Challenger carried out the first ever scientific oceanographic expedition from 1872-1876. One of the reasons we still are applying this crude technique today is because of its uncanny effectiveness. It allows us to rake together bags full of  basaltic samples in a relatively short amount of time and from targets far away in the middle of the ocean. Up until now we have done so successfully for 28 out of 31 dredges from as many seamounts in the waters of Tuvalu, Wallis and Samoa in the equatorial Pacific.

basaltic samples in a relatively short amount of time and from targets far away in the middle of the ocean. Up until now we have done so successfully for 28 out of 31 dredges from as many seamounts in the waters of Tuvalu, Wallis and Samoa in the equatorial Pacific.

However, dredging is not always successful, nor does it go smoothly all the time. In a few cases we might collect rocks other than basalts, such as limestones, coral debris and manganese encrustments. Sometimes our dredges may come back up empty. We simply consider these dredges unsuccessful because they didn’t deliver the basaltic rocks we are after during this expedition.

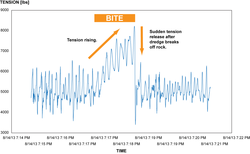

More often than not the dredge gets stuck while it is being dragged along the ocean floor at depths between 1 and 5 km. Maybe surprisingly to the novice dredger, this actually is a good situation, as the dredge now may be hung up on an outcrop that is of volcanic nature and of interest to the principal investigators on board. With the dredge stuck on the ocean floor, tension will rise on the wire until it breaks off the rock, which results in a sudden tension drop (Figure 2). We call that a “bite” and we hope that the broken off rock pieces actually get swallowed by the dredge mouth and collected in its chain-link bag that follows behind it. That way we can haul valuable rock samples from seamounts back up to the surface.

Depending on the size of the tension drop we record those as small (6,000-8,000 lbs), medium (8,000-10,000 lbs) and large (>10,000 lbs) bites in our dredging logs. As we drag these dredges over the ocean floors, along tracks 2 to 4 km in length, we typically get many bites. Although it is better to have more bites than less, it does not always guarantee that more rocks are filling up the dredge bag.

Depending on the size of the tension drop we record those as small (6,000-8,000 lbs), medium (8,000-10,000 lbs) and large (>10,000 lbs) bites in our dredging logs. As we drag these dredges over the ocean floors, along tracks 2 to 4 km in length, we typically get many bites. Although it is better to have more bites than less, it does not always guarantee that more rocks are filling up the dredge bag.

Many things can go wrong while we are dragging the dredges over the ocean floor. Uncommon is that the dredge lands wrong or curls up on the ocean floor. We can typically circumvent this situation by picking out a good landing spot by studying our bathymetric maps and by lowering the dredge slowly (~45 m per minute) while also slowly moving the ship forward. More common is that we cannot get loose from a big and sturdy outcrop of volcanic rocks on the ocean floor. Simply put, the rocks will not give away, even when we are pulling on the wire (by hauling in slowly) or dragging the dredge bucket along the track with the ship moving along the dredge track (at ~0.5 knt). Now we are literally stuck on the ocean floor and it requires special maneuvers and measures to get “unstuck” with the dredge again.

When repeated pulling and pulsing of the wire tension doesn’t work, the restech (i.e. the marine technician carrying out the dredging) will call the bridge letting them know we are stuck with the dredge and requesting that the ship come to a full stop. Now a slow chess play ensues. The ship is maneuvered back along the track line, perpendicular to the line, basically in all directions allowed by the prevailing wind and currents at that location, while paying out and hauling in wire in different ways (Figure 3). The goal is to get the dredge to release from the obstruction by angling the wire differently with respect to the stuck dredge. As the ship only moves about 0.5 kn in either direction, these maneuvers are slow and take up quite a lot of our operational time.

In most of the cases, we release the dredge this way; yet in some cases the dredge can be wedged into the seafloor pretty severely, maybe having itself (or the wire above it) trapped in a fissure or any other rock crevices. Essentially, we would be anchored to the ocean floor, if there was no other way to release the trapped dredge.

In most of the cases, we release the dredge this way; yet in some cases the dredge can be wedged into the seafloor pretty severely, maybe having itself (or the wire above it) trapped in a fissure or any other rock crevices. Essentially, we would be anchored to the ocean floor, if there was no other way to release the trapped dredge.

For that reason, several backup measures have been put into place to help us get unstuck in these tricky situations. As a fail-safe, three weak links are inserted into the dredge in strategic places. Two smaller, less strong weak links are inserted on two of its corners, but at the same side of the dredge; a third, stronger weak link is inserted close to where the chain link cables from the dredge are attached to the wire. These weak links are basically bolds that are rated to withstand a certain range in shear strength. This means that these bolts will shear off once the wire tension is brought up above those (combined) strengths. The two small weak links will shear off first, forcing the dredge to go sideways and making it possible to pull the dredge free from the obstruction.

If the above option doesn’t work, the wire tension can be increased even more to shear off the main weak link. Now no chain link cables are attached to the corners of the dredge anymore and the bag gets turned upside down by a “fifth” cable attached to the bottom of the dredge bag and where the wire meets the dredge at the top. In the end, when all measures fail and the dredge remains stuck, one of our last resorts is to increase tension even further to shear off the main shackle that holds the dredge onto the wire and sacrifice the dredge bag by leaving it on the ocean floor.

The final action to free ourselves from the ocean floor is to sever the wire. This last action is costly, as we will lose kilometers of expensive wire, but these situations are exceptionally rare and in all my seven dredging cruises so far, we never had to resort to this most extreme measure. Getting unstuck is a sometimes unnerving but unavoidable part of dredging operations.

- Anthony Koppers

- 4445 reads